Basic Info

Model No.: Dia15-300mm

Click on the follow link to find out more information: https://www.zhongyangscrew.com/extruder-single-screw-and-barrel/

Company Info

- Company Name: Zhejiang Zhongyang Screw Manufacturing Co., Ltd.

- Representative: JUNBING YANG

- Product/Service: Screw Element And Segmented Barrel , Injection Molding Machine Screw Barrel , Single Extruder Screw Barrel , Extruder Screw And Barrel , Screw And Barrel , Extruder Single Screw Barrel

- Capital (Million US $): 5,000,000RMB

- Year Established: 2009

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 6

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: XIHOU INDUSTRIAL PARK ,JINTANG TOWN,ZHOUSHAN ,CHINA

- Contact Person: Ms. Mia

- Tel: 86-580-8055067

Premium Related Products

Other Products

Hot Products

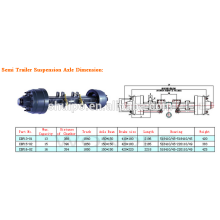

Semi trailer landing gearNo Template Irregular Dished Head Folding Machine(tank end pressing machine)Automatic Semitrailer Production Line(Trailer Equipment)Flat Butt Automatic Welding Machine/mig welding machineDish head bending machine/Cylinder head flanging machine/elliptical head flanging machine2014 High Evaluation steel cutting machineSHUIPO tank rolling machine/tank truck machineHydraulic Tank Head Forming Machine(Tank Truck Machine)CNC Plasma /Flame Cutting Machine(metal cutting machine)Turnover machineGantry Longitudinal Welding Machine(Arc welding machine)Landing Leg Welding Machine welding machinerySteel Sheet TurningOver Machineautomatic tank welding machine / girth welding machinetank head machineFree Form Tank Head Folding Machine